Az sonra izleyeceklerinizi evde denemeyinBaşka bir forumda gördüm paylaşayım dedim sonuç inanılmaz

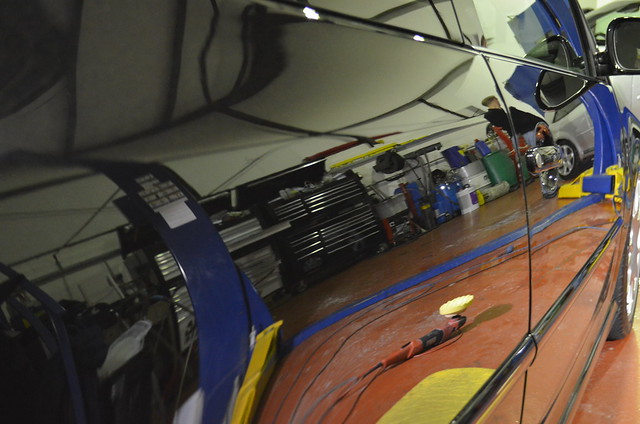

[QUOTE=RussZS;3184257]I’ve just been lucky enough to spend three days down at KDS Keltec with Kelly and his team, learning how to wet sand with the main aim of removing orange peel. Uniquely, this training was concluded on my very own car – a Golf GTI Edition 30 – with the aim of removing as much of the orange peel in my clearcoat as possible.

This thread shares my thoughts and experiences on the time spent with Kelly, and gives an overview from the perspective of a trainee on KDS’s course.

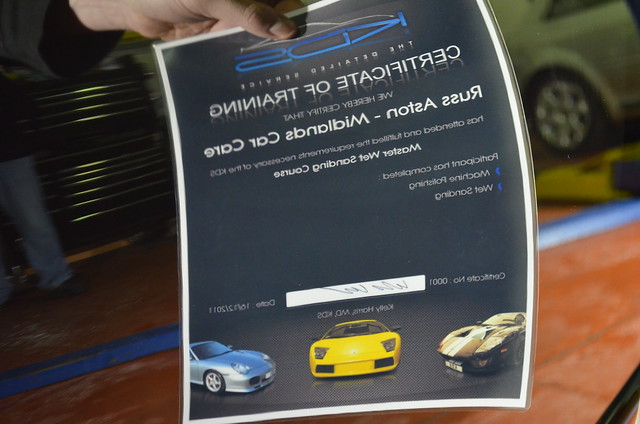

I ** also very fortunate to be the first - I have Certificate 0001!!

Day One :

It’s not very often I get out of bed at 5am, but I needed to be at KDS for 9am for my wet sanding training, so like an excited child on Christmas morning, I was up bright and early and set on my way. I’d forgotten just how bad the M1 and M25 were and unfortunately arrived 15 minutes late!

Upon arrival at KDS’s unit in Gillingham, Kent:

DSC01420 by RussZS, on Flickr

DSC01421 by RussZS, on Flickr

With introductions out of the way (Kelly has a team of 4 including himself), Kelly began to prepare a bonnet which would be the test panel for the first days worth of tuition:

DSC01422 by RussZS, on Flickr

The aim of the first day was to cover the following areas:

- Use of a Laser Pointer to create a fixed point to assess clearcoat removal rates

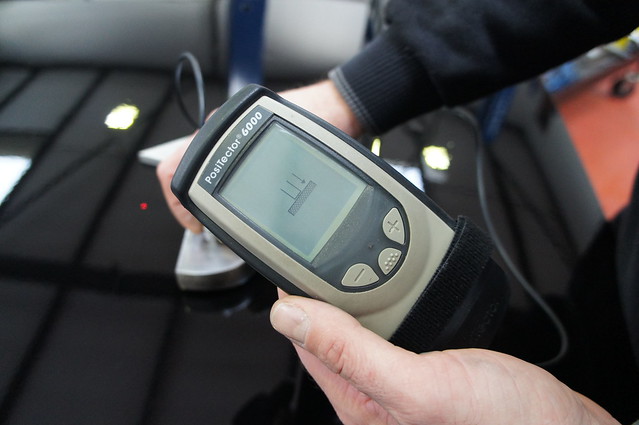

- How to use a PDG effectively, including how to calibrate one correctly

- The differences between using a DA Sander, working by bare hand and using a block

- Risks around scorelines, pigtailing and dirt/grit

- Using compounds and polishes to remove sanding marks and restoring the gloss to the paint

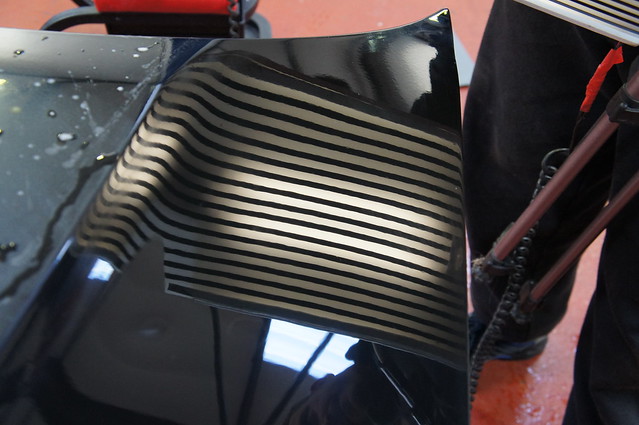

The test panel itself was absolutely ideal – covered in dents, RDS’s and crucially orange peel:

DSC01430 by RussZS, on Flickr

DSC01428 by RussZS, on Flickr

DSC01432 by RussZS, on Flickr

It’s almost as bad as a new BMW!!:lol:

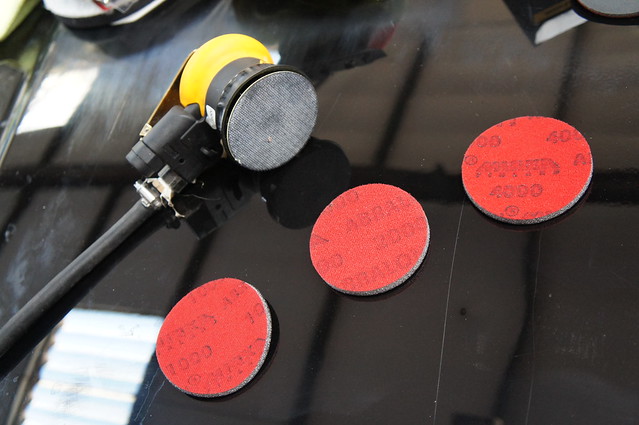

Here are some pics of the tools we used during the first day:

DSC01435 by RussZS, on Flickr

DSC01436 by RussZS, on Flickr

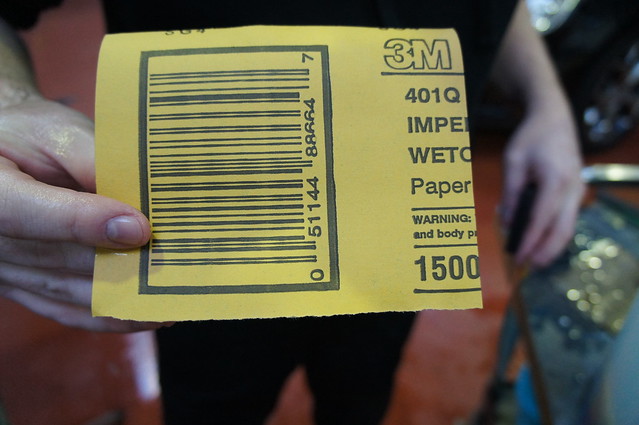

So we have:

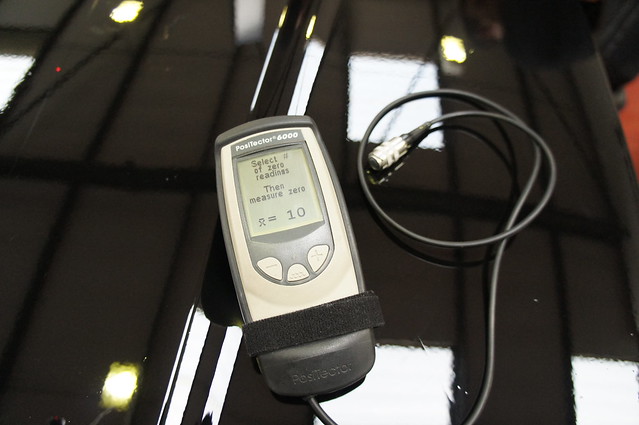

- PosiTector 6000

- Mirka DA Sanders and Abralon Discs

- 3M 1200, 1500 and 2000 grade sand paper

- Meguiars 2500, 3000 and 4000 grade sand paper

- Sanding Blocks

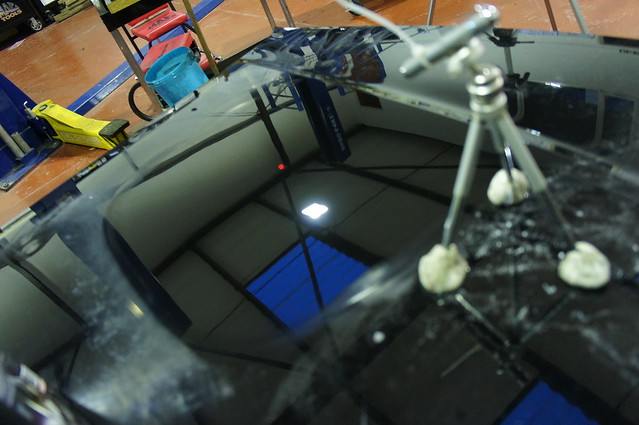

We set up the laser pointer on a tripod, secured by clay, to create a fixed point to allow us to as accurately as possible assess the removal rate of whatever we were doing.

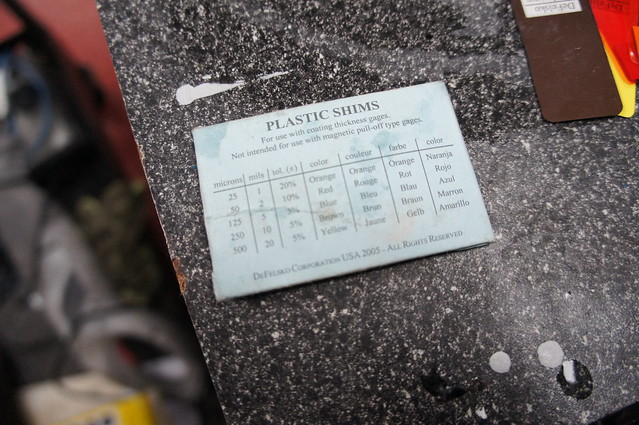

Next Kelly showed me how to correctly calibrate the PosiTector 6000:

DSC01448 by RussZS, on Flickr

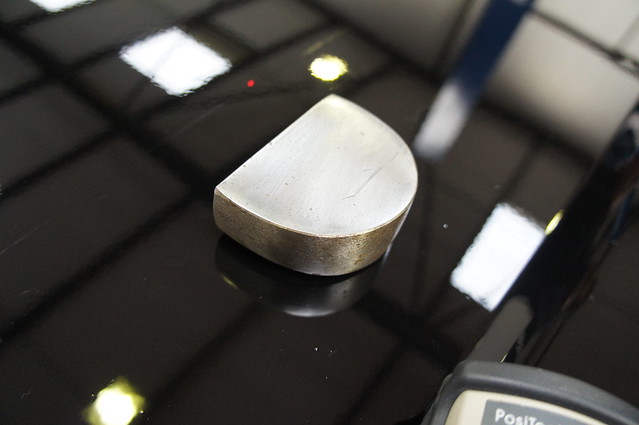

A bare metal block was used to create a reference point:

DSC01453 by RussZS, on Flickr

DSC01454 by RussZS, on Flickr

DSC01455 by RussZS, on Flickr

DSC01463 by RussZS, on Flickr

Next we tested with a shim:

DSC01467 by RussZS, on Flickr

DSC01468 by RussZS, on Flickr

That’s pretty close…

Now on a 125 shim:

DSC01484 by RussZS, on Flickr

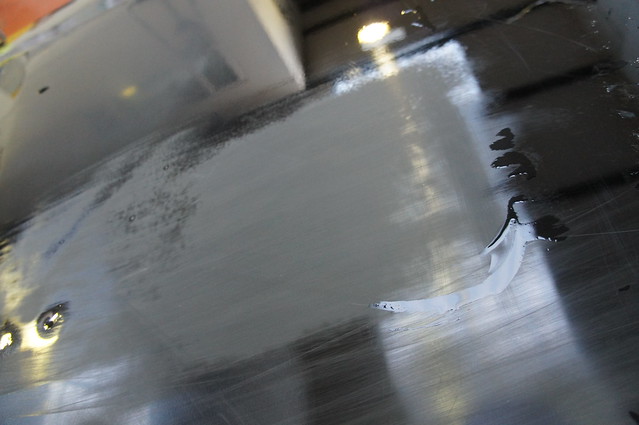

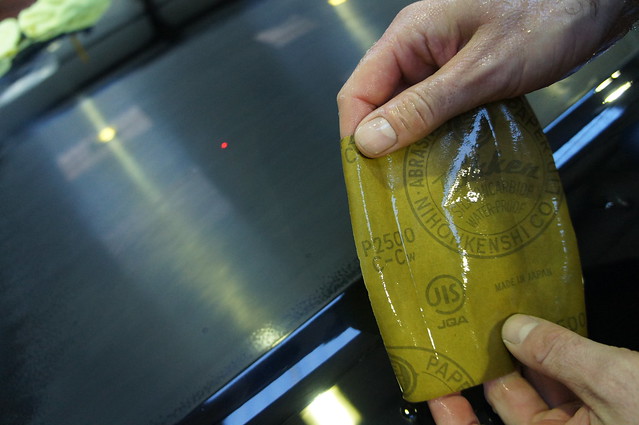

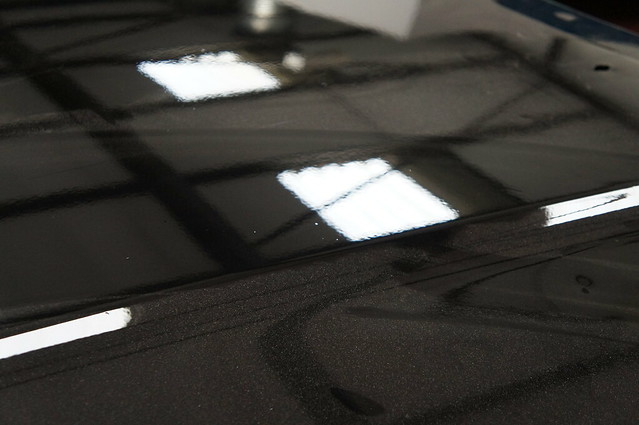

With the P6000 appropriately calibrated, Kelly moved on to begin the wet sanding demonstration. The key thing I have learnt about wet sanding is how important cleanliness is. If you catch a single dirt particle between the paper and the panel, the consequences can be severe. We began by flooding the panel, to remove any traces of dirt or dust:

DSC01499 by RussZS, on Flickr

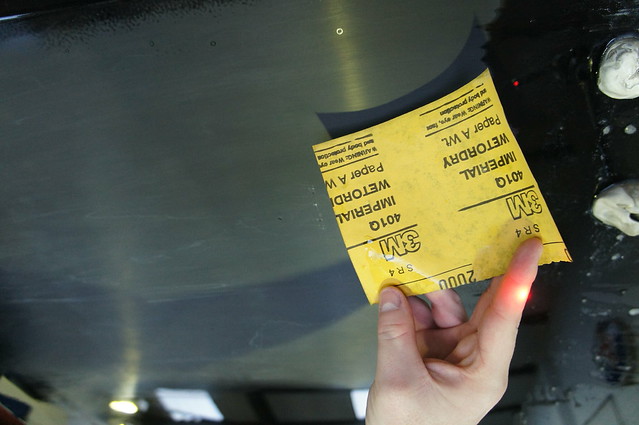

We began with 1500 grit. The paper was put into a bucket with warm water and hand wash (to help with lubricity):

DSC01502 by RussZS, on Flickr

Kelly began wet sanding by hand with 3M 1500

DSC01500 by RussZS, on Flickr

DSC01504 by RussZS, on Flickr

To deomstrate just how fine the ‘scratches’ from 1500 are, Kelly went over a test section with Lime Prime and Super Natural Hybrid:

DSC01514 by RussZS, on Flickr

DSC01516 by RussZS, on Flickr

DSC01519 by RussZS, on Flickr

Impressive stuff!! However, up close…

DSC01522 by RussZS, on Flickr

It just goes to show how deceiving some photos could be…

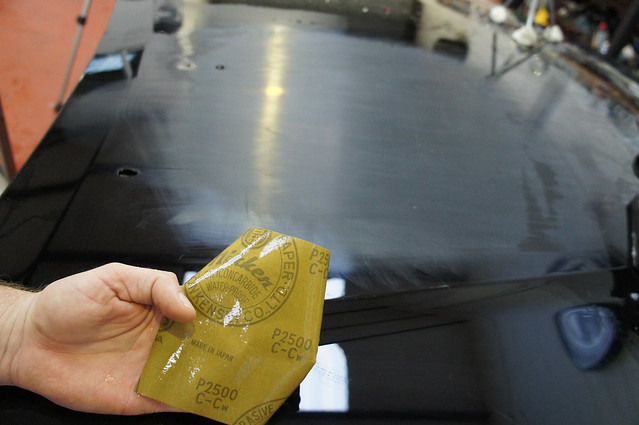

Next Kelly showed me how to use a Mirka DA Sander with 2000 grade disc:

DSC01528 by RussZS, on Flickr

DSC01535 by RussZS, on Flickr

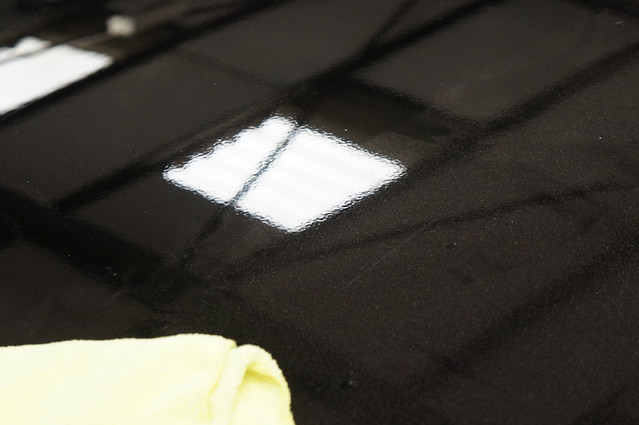

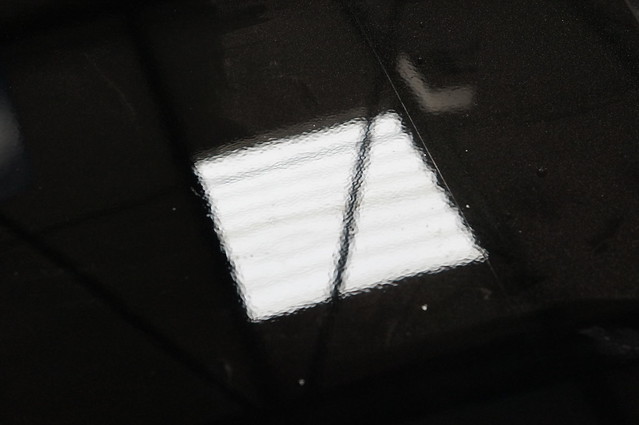

Now from certain angles, it would appear that the orange peel has been fully removed. I’ve seen a couple of threads where this process has been used, and from certain angles it looks perfectly flat:

DSC01533 by RussZS, on Flickr

However up close, at the right angle we can see the peel is still very much there!!

DSC01530 by RussZS, on Flickr

I then had my first go! 4000 Grit Abralon Pad on the Mirka, to refine the finish of the 2000:

DSC01542 by RussZS, on Flickr

DSC01541 by RussZS, on Flickr

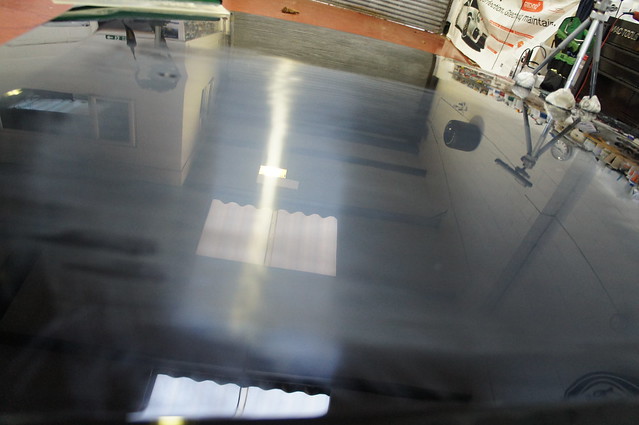

I was keen to try the 2000 myself to see if orange peel could be removed on a different part of the test panel:

DSC01548 by RussZS, on Flickr

However again, from certain angles it looks great – very flat:

DSC01551 by RussZS, on Flickr

However, catch the lighting correctly and we can see the peel is still present:

DSC01552 by RussZS, on Flickr

Meanwhile Kelly just off refining the other part of the test panel so that it was all at 4000 grit level:

DSC01560 by RussZS, on Flickr

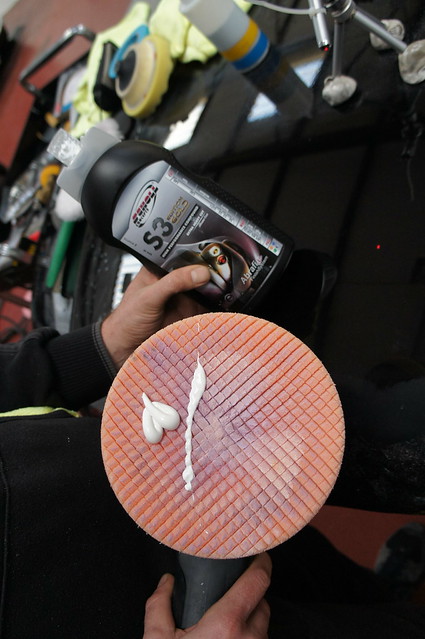

For fun, we tried P1 via a 4000 Grit Pad…

DSC01562 by RussZS, on Flickr

DSC01565 by RussZS, on Flickr

DSC01569 by RussZS, on Flickr

Alıntı

Alıntı